Busbar Plugs

Termate’s BP2X range of single pole busbar stab and insulator assemblies are an easy to install versatile busbar plug that achieves IP2X without the need for shutters or barriers.

The plug has been designed to be connected and disconnected off load.

- The range has 250 A and 400/630 A variants, suitable for use with 6 mm, 6.3 mm and 10 mm copper

- All variants have the same space footprint and utilise the same fixing method and dimensions, giving you consistency in design and manufacturing optimisation across a range of equipment ratings

- BP2X plugs have the potential to reach an Icc rating of 100 kA

The plug has not been designed to be self supporting and should be installed onto a suitable mounting plate.

BP2X250 & BP2X400

The following tables shows the Recognition, Properties and Characteristics of the Termate range of Bus Bar Plugs.

| Recognition | Reference / Link | Preferred name |

|---|---|---|

| UL Recognised Component | File Number: E505645 | |

| EClass 14.0 | 27-44-07-90 | Power plug connector (unspecified) |

| Properties | Value / Measure / Unit |

|---|---|

| Insulator Material | Glass Reinforced Polyamide 6.6 (PA66) |

| Flammability | UL 94 V-0 |

| Oxygen Index | 32% |

| Glow Wire | 960 °C |

| Contact Material | Silver Plated Copper |

| Max. Conductor Temp. in Celsius† | +105 °C |

| Max. Conductor Temp. in Fahrenheit† | +221 °F |

| Characteristics | Value |

|---|---|

| Maximum Alternating Current Equipment Voltage, Ue | 1000 V |

| Maximum Direct Current Equipment Voltage, Ue | 1500 V |

| Impulse Voltage, Uimp | 12 kV |

BP2X Busbar Plug—Test Results

| Part Number | 3D Model | Current Rating* | Temperature Rise | Fixed Conductor Size (mm) | Tested Ipk (No SCPD) | Estimated Protected Short Circuit Rating Icc** |

|---|---|---|---|---|---|---|

| BP2X250-6 | BP2X250 STEP file | 250 A | 29 K | 6.0/6.3 | 30 kA | 100 kA |

| BP2X250-10 | BP2X250 STEP file | 250 A | 29 K | 10 | 30 kA | 100 kA |

| BP2X400-6 | BP2X400 STEP file | 400 A/630 A | 29 K (400 A) or 47 K (630 A) | 6.0/6.3 | 40 kA | 100 kA |

| BP2X400-10 | BP2X400 STEP file | 400 A/630 A | 29 K (400 A) or 47 K (630 A) | 10 | 40 kA | 100 kA |

The testing of our busbar plugs was carried out inline with IEC 61439-2, Edition 2, 2011. Please contact us for additional technical queries.

* The unenclosed ratings were tested based on an ambient of 35 °C with test conditions as declared in IEC 61439 with temperature rise as shown.

** This figure is based on an assessment of multiple devices peak let through current. The specific peak let through current for the selected SCPD should be confirmed not to exceed the Ipk declared.

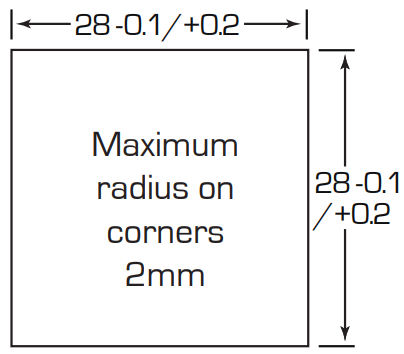

Mounting Plate Cut-Out Detail:

Termate recommends that any cutting made after the finish has been applied, should be treated to ensure compliance with IEC 61439-1 section 10.2.2 (resistance to corrosion).

Care should be taken to ensure that the mounting plate exhibits sufficient mechanical strength consistent with the Busbar Plugs being inserted and withdrawn multiple times. Experience, judgement and good engineering practice should always be applied.

Recommended Maintenance

- Moving assemblies are inspected within every 200 operations or immediately after any form of short circuit

- Unplug or withdraw the moving assembly

- Visually inspect all components for damage or signs of arcing, damaged or worn components should be further inspected or replaced as required

- Clean and re-grease any moving electrical contacts with a suitable electrical grade lubricant

- Clean and re-grease any moving mechanical parts with a suitable lubricant

- Check tightness of any fixings

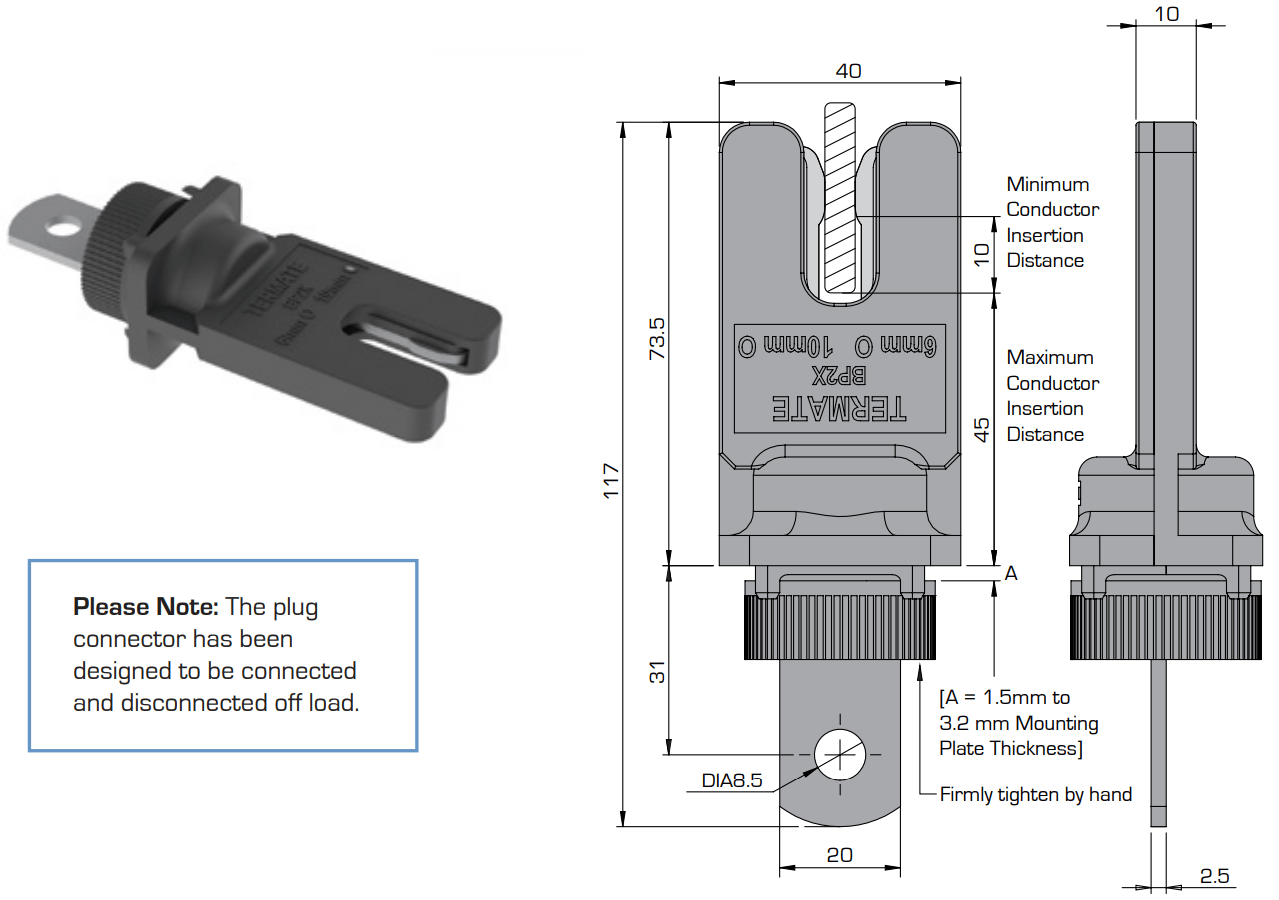

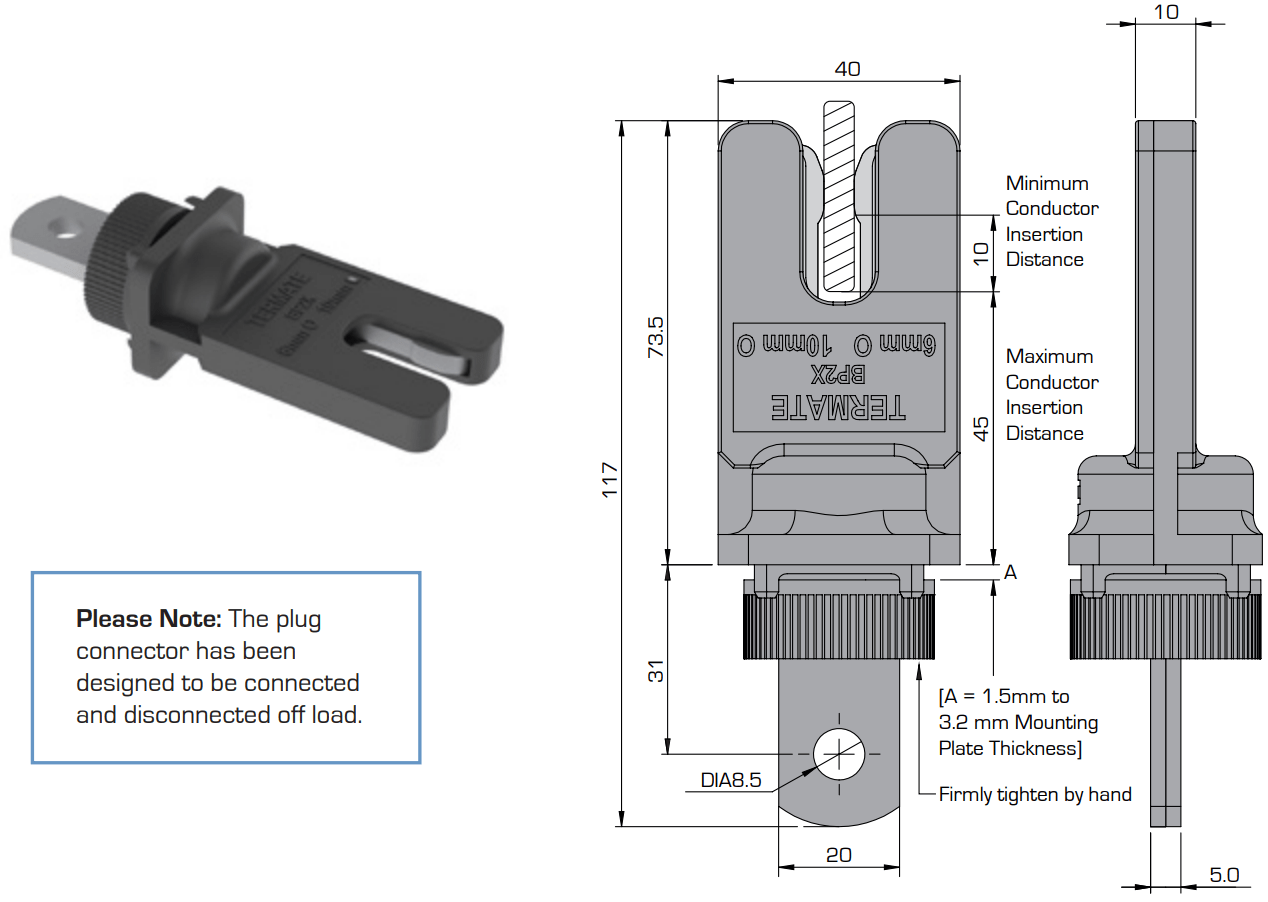

BP2X Busbar Plug—Dimensions

BP2X250

BP2X400

Typical Installation

Busbar plug attached to mounting plate and connected to conductor

BP2X busbar plugs provide a variety of advantages over other types of electrical connection systems. They offer increased safety and protection against potential damage due to their design and material strength, making them an ideal choice for high-traffic areas with multiple moving parts.

Additionally, their compact size makes them highly efficient in terms of space utilization, allowing for more freedom in your design and installation.

They are also tested and developed to withstand the temperatures anticipated during both normal and fault conditions in addition to other environmental factors, making them well-suited for use in pharmaceutical, marine and other critical applications.

Finally, BP2X bus bar stab and insulator assemblies provide superior reliability due to their ability to remain securely connected even with high levels of vibration or movement; this is especially important in sensitive electrical systems.

Termate is committed to the highest standard of customer focus and we have made every effort to maintain the accuracy and completeness of the information provided in this data. Where improvements to our products affect their installation and usage we endeavour to contact any customers who may be affected.

Warranty as stated in our Terms and Conditions of Trading is void if any modification is made to the warranted product.