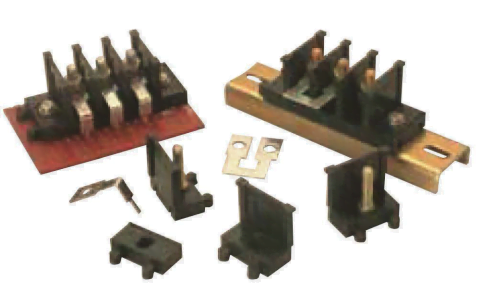

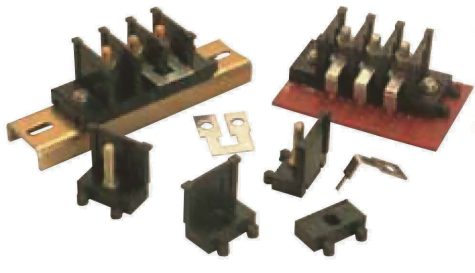

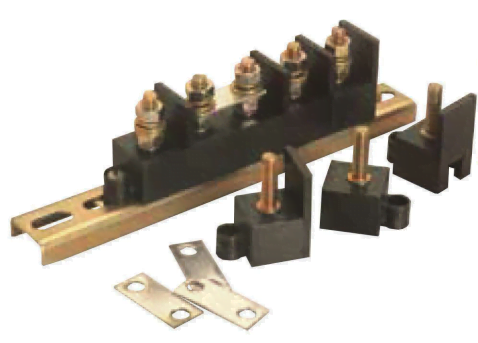

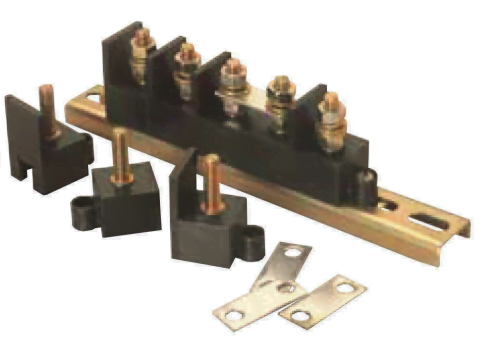

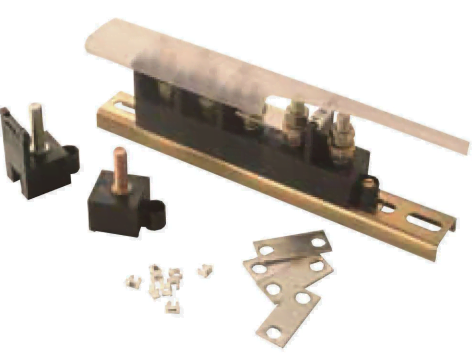

Terminals

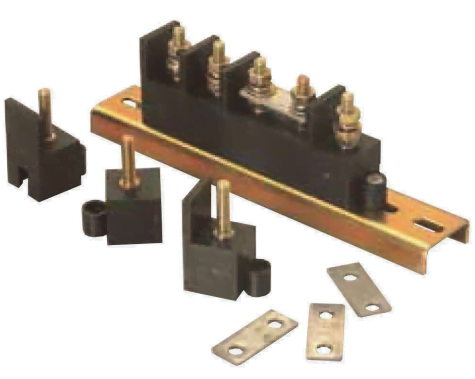

Termate’s stud type terminal ranges have been core products ever since the inception of the company. The ranges cover stud sizes from M4 up to M12 with fixing bases of 11 mm² through to 50 mm².

Accessories including mounting rail, covers, links and terminal markers allow the easy creation of terminal assemblies.

The KM motor terminal block range was discontinued on the 1st January 2022. We continue to manufacture and distribute our heavy-duty study-type terminals, as well as single and twin interlocking stud-type terminals, as they are in no way affected by these changes.

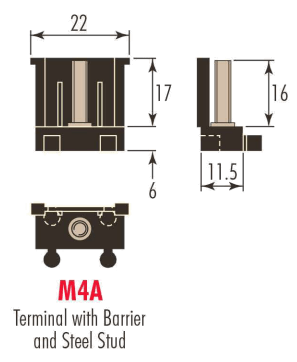

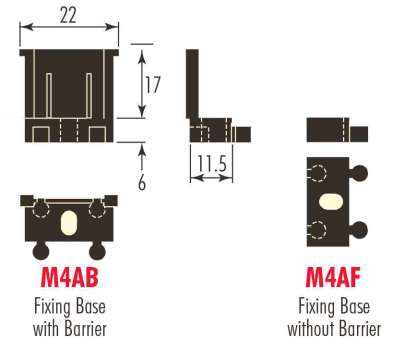

M4A Interlocking Terminals - M4 Steel Thread - Stud Type

- Base Material: Polyamide 6 with Low Smoke Emissions & Flame Retardant

- Flammability Classification: Low Smoke NFF16 -101/102 I2/F3

- Colour: Black

- Working Temperature: 80–110 °C

(long term) - UL Approval: UL 94 V-0 (0.8 mm)

- Stud Material: Male—Mild Steel Zinc and Passivate

- Tread: Isometric Medium Fit Coarse Thread Class 6H/6g

- CTI: 575V IEC 60112

- Working Voltage (Ue): 250 V (BS 2618)

- Maximum Tightening Torque (stud): 2.0 N·m

- Maximum Recommended Cable Shoe Size: 6 mm²

M4A Interlocking Terminals - M4 Brass Thread - Stud Type

- Base Material: Polyamide 6 with Low Smoke Emissions & Flame Retardant

- Flammability Classification: Low Smoke NFF16 -101/102 I2/F3

- Colour: Black

- Working Temperature: 80–110 °C (long term)

- UL Approval: UL 94 V-0 (0.8 mm)

- Stud Material: Brass—Bright Dipped

- Tread: Isometric Medium Fit Coarse Thread Class 6H/6g

- CTI: 575V IEC 60112

- Working Voltage (Ue): 250 V (BS 2618)

- Maximum Tightening Torque (stud): 2.0 N·m

- Maximum Recommended Cable Shoe Size: 6 mm²

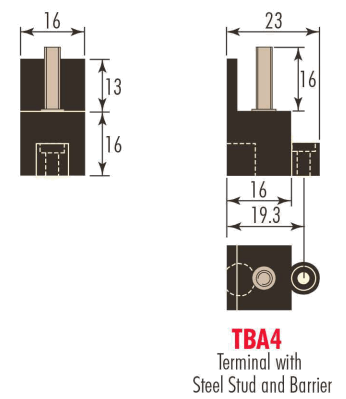

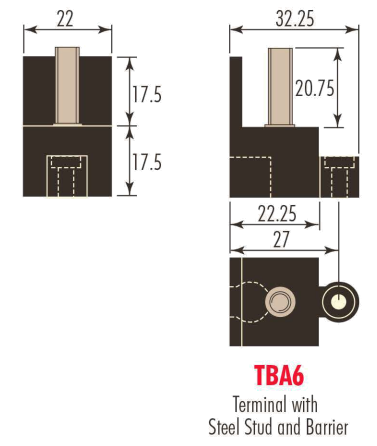

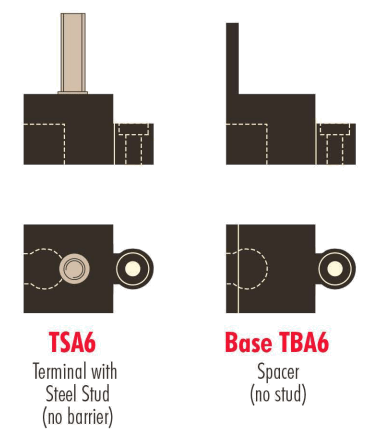

TBA Interlocking Terminals - M4 Steel Thread - Stud Type

- Base Material: Polyamide 6 with Low Smoke Emissions & Flame Retardant

- Flammability Classification: Low Smoke NFF16 -101/102 I2/F3

- Colour: Black

- Working Temperature: 80–110 °C (long term)

- UL Approval: UL 94 V-0 (0.8mm)

- Stud Material: Male—Mild Steel Zinc & Passivate

- Tread: Isometric Medium Fit Coarse Thread Class 6H/6g

- CTI: 575V IEC 60112

- Working Voltage (Ue): 250 V (BS 2618)

- Maximum Tightening Torque (stud): 2.0 N·m

- Maximum Recommended Cable Shoe Size: 6 mm²

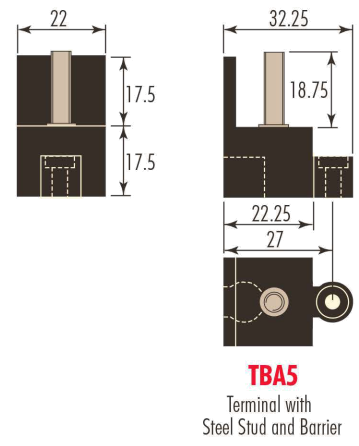

TBA Interlocking Terminals - M5 Steel Thread - Stud Type

- Base Material: Polyamide 6 with Low Smoke Emissions & Flame Retardant

- Flammability Classification: Low Smoke NFF16 -101/102 I2/F3

- Colour: Black

- Working Temperature: 80–110 °C (long term)

- UL Approval: UL 94 V-0 (0.8 mm)

- Stud Material: Male—Mild Steel Zinc & Passivate

- Tread: Isometric Medium Fit Coarse Thread Class 6H/6g

- CTI: 575V IEC 60112

- Working Voltage (Ue): 600 V (BS 2618)

- Maximum Tightening Torque (stud): 4.0 N·m

- Maximum Recommended Cable Shoe Size: 16 mm²

TBA Interlocking Terminals - M6 Steel Thread - Stud Type

- Base Material: Polyamide 6 with Low Smoke Emissions & Flame Retardant

- Flammability Classification: Low Smoke NFF16 -101/102 I2/F3

- Colour: Black

- Working Temperature: 80–110 °C (long term)

- UL Approval: UL 94 V-0 (0.8 mm)

- Stud Material: Male—Mild Steel Zinc & Passivate

- Tread: Isometric Medium Fit Coarse Thread Class 6H/6g

- CTI: 575V IEC 60112

- Working Voltage (Ue): 600 V (BS 2618)

- Maximum Tightening Torque (stud): 6.8 N·m

- Maximum Recommended Cable Shoe Size: 35 mm²

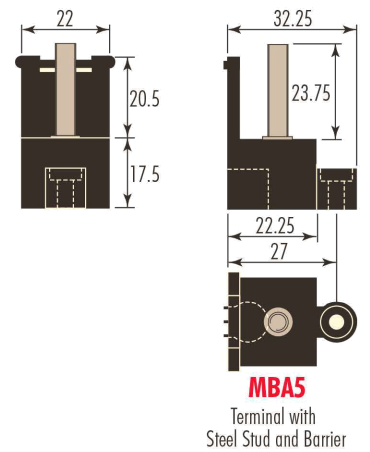

MBA Interlocking Terminals - M5 Steel Thread - Stud Type

- Base Material: Polyamide 6 with Low Smoke Emissions & Flame Retardant

- Flammability Classification: Low Smoke NFF16 -101/102 I2/F3

- Colour: Black

- Working Temperature: 80–110 °C (long term)

- UL Approval: UL 94 V-0 (0.8 mm)

- Stud Material: Male—Mild Steel Zinc & Passivate

- Tread: Isometric Medium Fit Coarse Thread Class 6H/6g

- CTI: 575V IEC 60112

- Working Voltage (Ue): 600 V (BS 2618)

- Maximum Tightening Torque (stud): 4.0 N·m

- Maximum Recommended Cable Shoe Size: 16 mm²

MBA Interlocking Terminals - M6 Steel Thread - Stud Type

- Base Material: Polyamide 6 with Low Smoke Emissions & Flame Retardant

- Flammability Classification: Low Smoke NFF16 -101/102 I2/F3

- Colour: Black

- Working Temperature: 80–110 °C (long term)

- UL Approval: UL 94 V-0 (0.8 mm)

- Stud Material: Male—Mild Steel Zinc & Passivate

- Tread: Isometric Medium Fit Coarse Thread Class 6H/6g

- CTI: 575V IEC 60112

- Working Voltage (Ue): 600 V (BS 2618)

- Maximum Tightening Torque (stud): 6.8 N·m

- Maximum Recommended Cable Shoe Size: 35 mm²

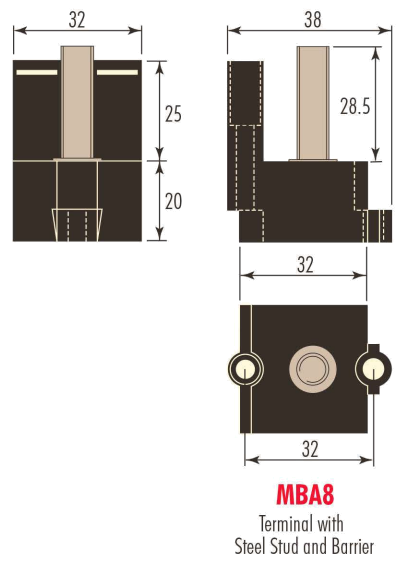

MBA Interlocking Terminals - M8 Steel Thread - Stud Type

- Base Material: Polyamide 6 with Low Smoke Emissions & Flame Retardant

- Flammability Classification: Low Smoke NFF16 -101/102 I2/F3

- Colour: Black

- Working Temperature: 80–110 °C (long term)

- UL Approval: UL 94 V-0 (0.8 mm)

- Stud Material: Male—Mild Steel Zinc & Passivate

- Tread: Isometric Medium Fit Coarse Thread Class 6H/6g

- CTI: 575V IEC 60112

- Working Voltage (Ue): 750 V (BS 2618)

- Maximum Tightening Torque (stud): 16.5 N·m

- Maximum Recommended Cable Shoe Size: 50 mm²

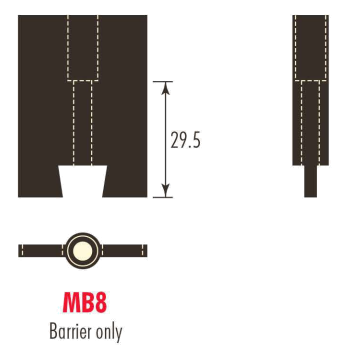

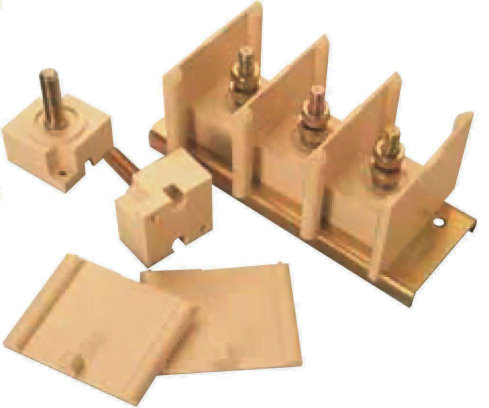

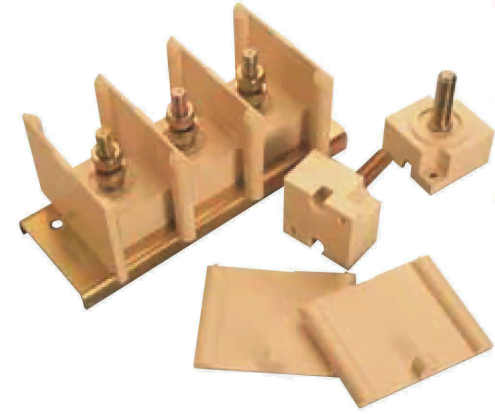

Heavy Duty Terminals - M10 Steel Thread - Stud Type

- Base Material: Glass Fibre Reinforced Polyester DMC with High Arc Resistance and Reduced Flammability

- Colour: Beige

- Working Temperature: 160 °C

- Oxygen Index: 30% BS2782 method 141 ISO 4589

- UL Approval: UL 94 V-0

- Stud Material: Male—Mild Steel Zinc & Passivate

- Tread: Isometric Medium Fit Coarse Thread Class 6H/6g

- CTI: > 600V BS 5901 IEC 112

- Working Voltage (Ue): 1200 V (BS 2618)

- Maximum Tightening Torque (stud): 32.8 N·m

- Maximum Recommended Cable Shoe Size: 185 mm²

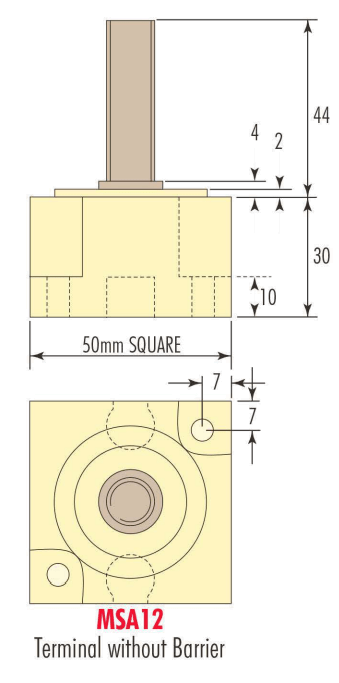

Heavy Duty Terminals - M12 Steel Thread - Stud Type

- Base Material: Glass Fibre Reinforced Polyester DMC with High Arc Resistance and Reduced Flammability

- Colour: Beige

- Working Temperature: 160 °C

- Oxygen Index: 30% BS 2782 method 141 ISO 4589

- UL Approval: UL 94 V-0

- Stud Material: Male—Mild Steel Zinc & Passivate

- Tread: Isometric Medium Fit Coarse Thread Class 6H/6g

- CTI: > 600V BS 5901 IEC 112

- Working Voltage (Ue): 1200 V (BS 2618)

- Maximum Tightening Torque (stud): 57.0 N·m

- Maximum Recommended Cable Shoe Size: 240 mm²

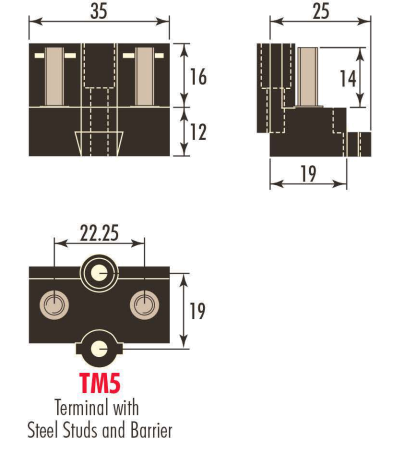

TM5 Interlocking Terminals - M5 Steel Thread - Twin Stud Type

- Base Material: Polyamide 6 with Low Smoke Emissions & Flame Retardant

- Flammability Classification: Low Smoke NFF16 -101/102 I2/F3

- Colour: Black

- Working Temperature: 80–110 °C (long term)

- UL Approval: UL 94 V-0 (0.8 mm)

- Stud Material: Male—Mild Steel Zinc & Passivate

- Tread: Isometric Medium Fit Coarse Thread Class 6H/6g

- CTI: 575V IEC 60112

- Working Voltage (Ue): 600 V (BS 2618)

- Maximum Tightening Torque (stud): 4.0 N·m

- Maximum Recommended Cable Shoe Size: 16 mm²

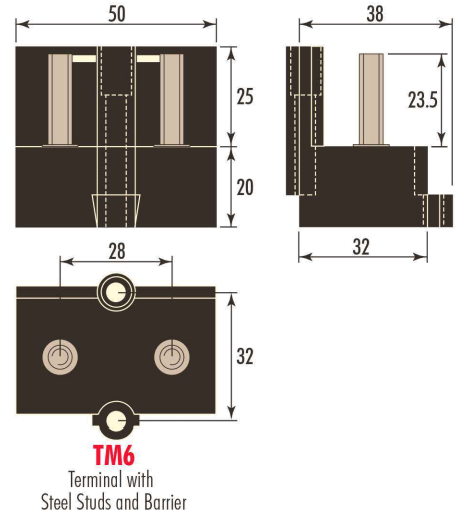

TM6 Interlocking Terminals - M6 Steel Thread - Twin Stud Type

- Base Material: Polyamide 6 with Low Smoke Emissions & Flame Retardant

- Flammability Classification: Low Smoke NFF16 -101/102 I2/F3

- Colour: Beige

- Working Temperature: 80–110 °C (long term)

- UL Approval: UL 94 V-0 (0.8 mm)

- Stud Material: Male—Mild Steel Zinc & Passivate

- Tread: Isometric Medium Fit Coarse Thread Class 6H/6g

- CTI: 575V IEC 60112

- Working Voltage (Ue): 750 V (BS 2618)

- Maximum Tightening Torque (stud): 6.8 N·m

- Maximum Recommended Cable Shoe Size: 35 mm²

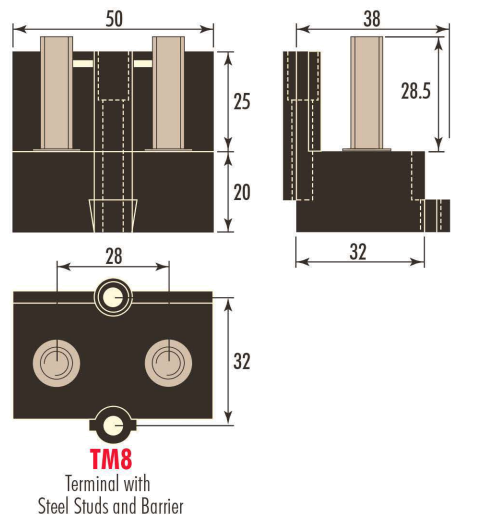

TM8 Interlocking Terminals - M8 Steel Thread - Twin Stud Type

- Base Material: Polyamide 6 with Low Smoke Emissions & Flame Retardant

- Flammability Classification: Low Smoke NFF16 -101/102 I2/F3

- Colour: Black

- Working Temperature: 80–110 °C (long term)

- UL Approval: UL 94 V-0 (0.8 mm)

- Stud Material: Male—Mild Steel Zinc & Passivate

- Tread: Isometric Medium Fit Coarse Thread Class 6H/6g

- CTI: 575V IEC 60112

- Working Voltage (Ue): 750 V (BS 2618)

- Maximum Tightening Torque (stud): 16.5 N·m

- Maximum Recommended Cable Shoe Size: 50 mm²

Accessories

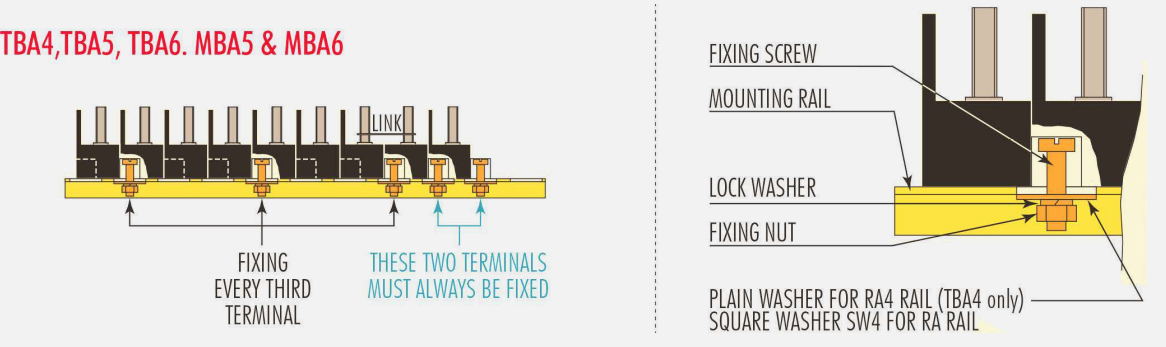

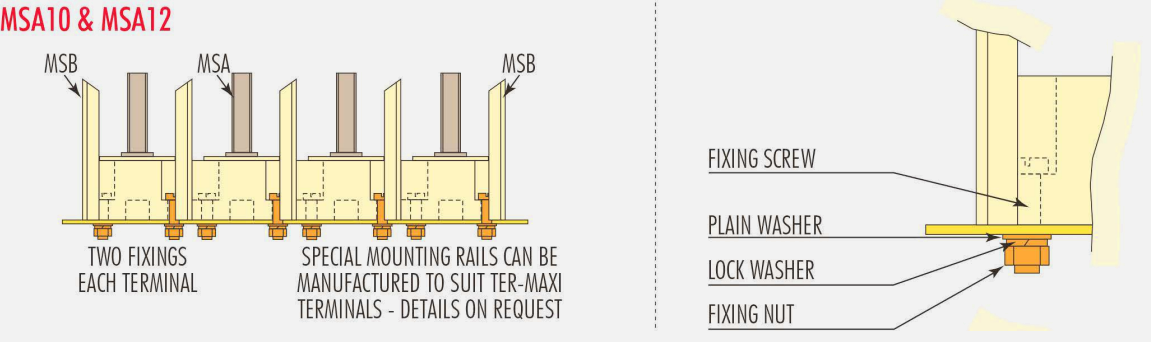

| Terminal Range | Part Number | Mounting Rail | Marker 0-9 A-Z | Cover | Link | Square Washer | Cover Fixing | Fixing Screw* Not of Termate supply. |

|---|---|---|---|---|---|---|---|---|

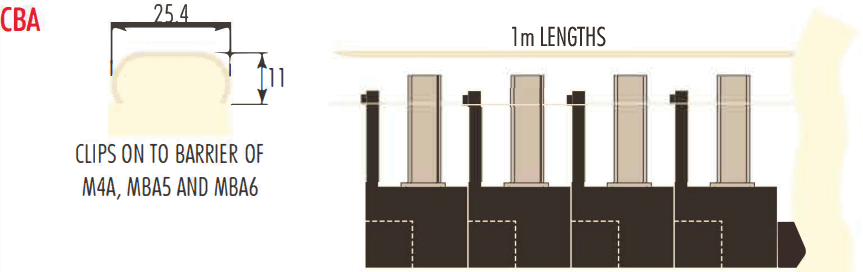

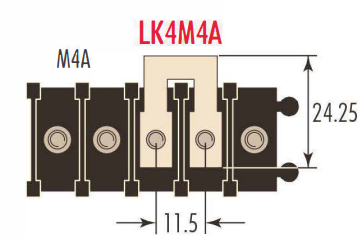

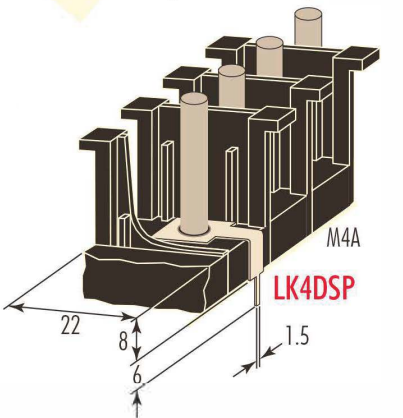

| TER-MINI | M4A/M4A BRASS | RA | 91506 | CBA | LKM4A LK4DSP† | SW4 | - | M4x16 |

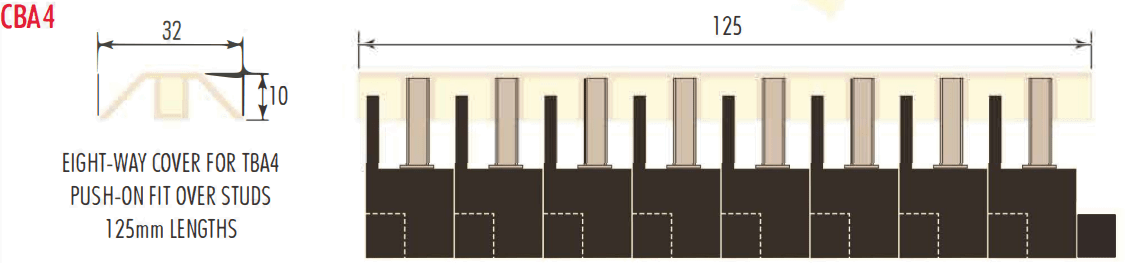

| TER-MIDI | TBA4/TSA4 | RA4 | - | CBA4 | LK4MS-A | - | - | M3x12 |

| TER-MIDI | TBA5/TSA5 | RA | - | - | LK5TM-A | SW4 | - | M4x16 |

| TER-MIDI | TBA6/TSA6 | RA | - | - | LK6A | SW4 | - | M4x16 |

| TER-MIDI | MBA5/MSA5 | RA | 91506 | CBA | LK5TM-A | SW4 | - | M4x16 |

| TER-MIDI | MBA6/MSA6 | RA | 91506 | CBA | LK6A | SW4 | - | M4x16 |

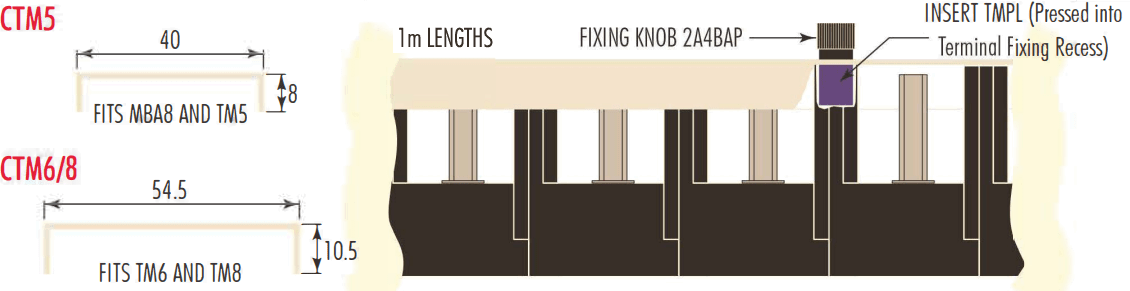

| TER-MIDI | MBA8 | RA8 | 91506 | CTM5 | - | - | 2A4BAP/TMPL | M4x40 |

| TER-MAXI | MSA10/MSA12 | RA12 | - | - | - | - | - | M5x20 |

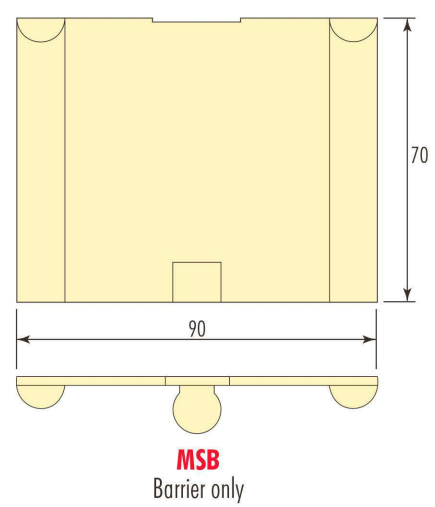

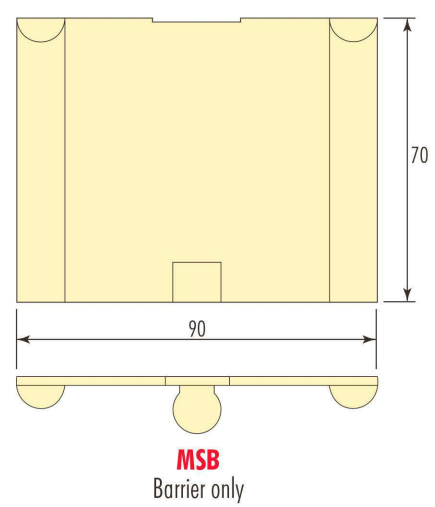

| TER-MAXI | (barrier) MSB | RA12 | 91506 | - | - | - | - | - |

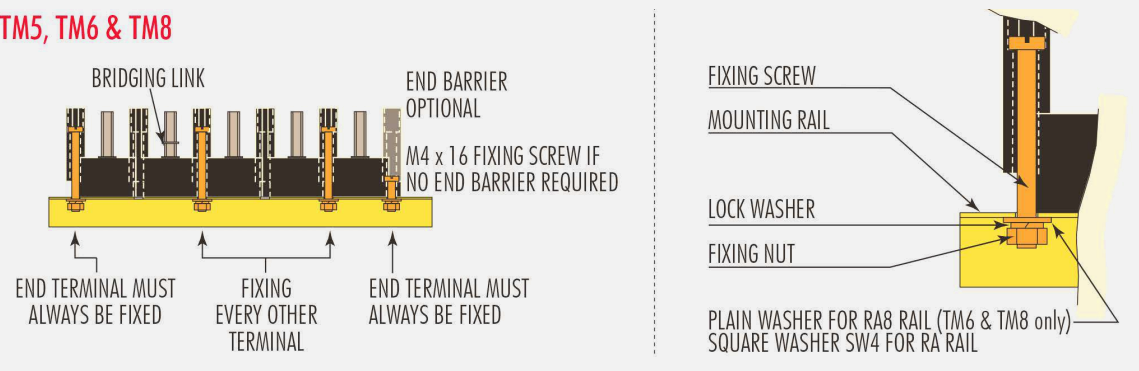

| TERMA-TWIN | TM5 | RA | 91506 | CTM5 | LK5TM-A | - | 2A4BAP/TMPL | M4x25 |

| TERMA-TWIN | TM6 | RA8 | 91506 | CTM6-8 | LK6TM | - | 2A4BAP/TMPL | M4x40 |

| TERMA-TWIN | TM8 | RA8 | 91506 | CTM6-8 | LK8TM | - | 2A4BAP/TMPL | M4x40 |

* Fixing screw length assumes stand mounting rail used.

† Drip Solder Pin

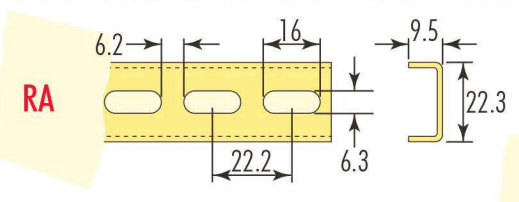

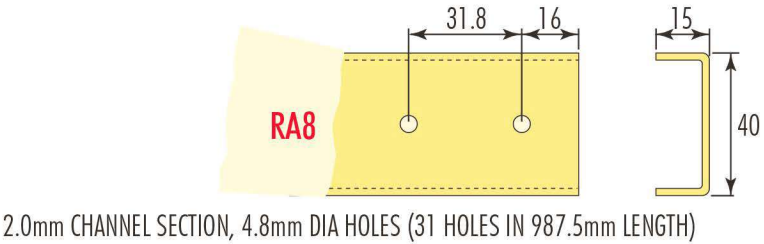

Mounting Rails

Supplied in 1 Metre lengths unless detailed otherwise.

Mild Steel—Zinc Plated and Passivate

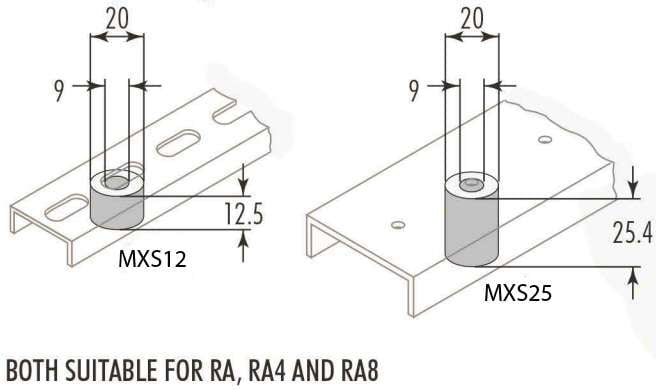

Mounting Rails Spacers

To support rail when fixing.

Markers 91506

Covers

Links

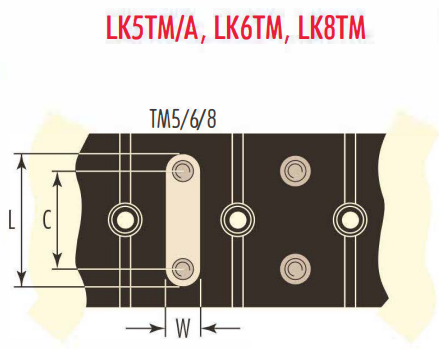

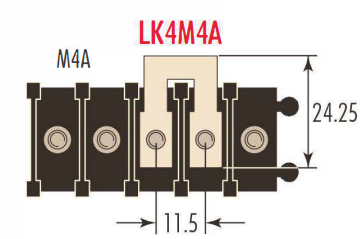

| Link Part Number | Current Rating Amps | L mm | W mm | Thickness mm | C mm | Dia holes mm |

|---|---|---|---|---|---|---|

| LK4MS/A | 15 | 25.4 | 10 | 1.00 | 16 | 4.2 |

| LK5TM/A | 25 | 33 | 10 | 1.50 | 22.26 | 5.5 |

| LK6A | 60 | 32 | 13 | 1.25 | 22 | 6.3 |

| LK6TM | 60 | 40 | 12 | 1.25 | 28 | 6.3 |

| LK8TM | 100 | 44 | 16 | 2.00 | 28 | 8.5 |

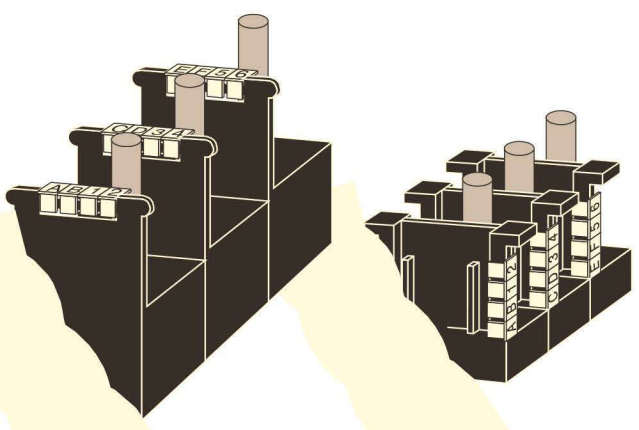

Assembly Details

Technical Data

| Part Number | Creepage Distance Terminal to Terminal (mm) | Creepage Distance Terminal to Earth (mm) | Clearance Distance Terminal to Terminal (measured with unfurnished studs) | Provision for Marker Tags |

|---|---|---|---|---|

| M4A | 20.5 | 7.5 | 7.5 | up to 4 per side |

| M4A BRASS | 20.5 | 7.5 | 7.5 | up to 4 per side |

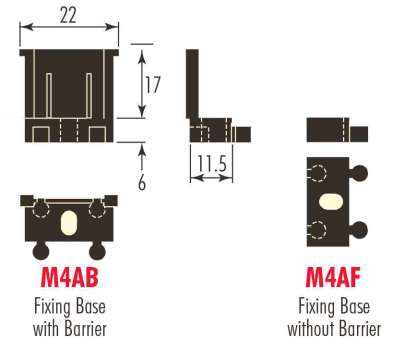

| M4AB | - | - | - | up to 4 per side |

| M4AF | - | - | - | - |

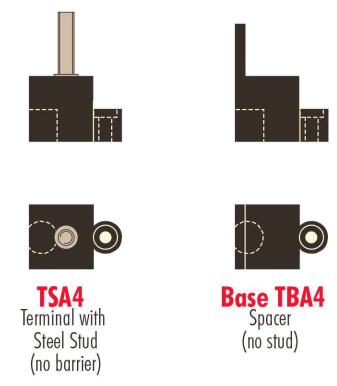

| TBA4 | 17.0 | 13.0 | 11.5 | - |

| TSA4 | 17.0 | 13.0 | 11.5 | - |

| Base TBA4 | - | - | - | - |

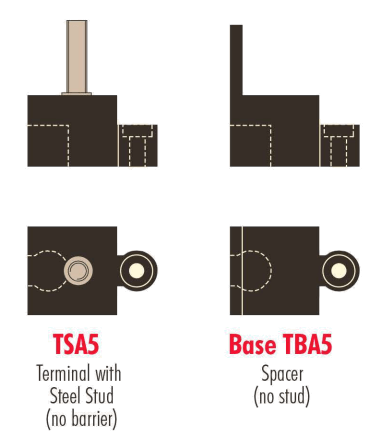

| TBA5 | 24.0 | 14.0 | 17.0 | - |

| TSA5 | 24.0 | 14.0 | 17.0 | - |

| Base TBA5 | - | - | - | - |

| TBA6 | 22.5 | 13.5 | 16.0 | - |

| TSA6 | 22.5 | 13.5 | 16.0 | - |

| MBA5 | 24.0 | 14.0 | 17.0 | Up to 4 |

| MSA5 | 24.0 | 14.0 | 17.0 | - |

| MBA6 | 22.5 | 13.5 | 16.0 | Up to 4 |

| MSA6 | 22.5 | 13.5 | 16.0 | - |

| Base MBA | - | - | - | Up to 4 |

| MBA8 | 22.5 | 22.0 | 24.0 | up to 6 |

| MB8 | - | - | - | up to 6 |

| MSA10 | 41.5 | 35.0 | 34.0 | - |

| MSA12 | 41.5 | 35.0 | 34.0 | - |

| MSB | - | - | - | up to 4 |

| TM5 | 15.0 | 13.0 | 14.0 | up to 6 |

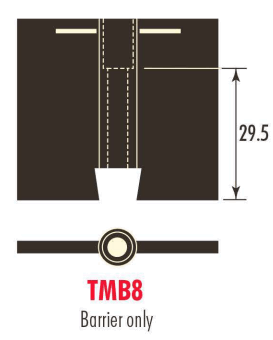

| TMB | - | - | - | up to 6 |

| Base TM5 | - | - | - | - |

| TM6 | 29.5 | 23.5 | 25.5 | up to 6 |

| TM8 | 25.5 | 22.0 | 24.0 | up to 6 |

| TMB8 | - | - | - | up to 6 |

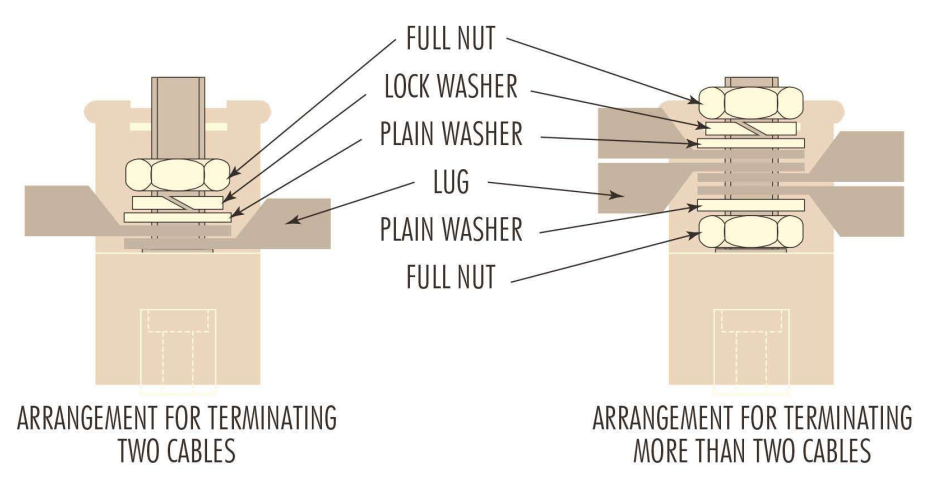

Methods of Terminating Connections

Each stud provides a bolting medium for two or more cables. This method of connection is particularly suitable where resistance to vibration is important.

Termate is committed to the highest standard of customer focus and we have made every effort to maintain the accuracy and completeness of the information provided in this data. Where improvements to our products affect their installation and usage we endeavour to contact any customers who may be affected.

Warranty as stated in our Terms and Conditions of Trading is void if any modification is made to the warranted product.