Why Termate provides detailed Mechanical Data on its Standoff Insulator range.

In addition to having appropriate electrical properties, the mechanical strength of a standoff insulator is essential for its ability to perform in normal and fault conditions. Termate provides three key performance characteristics to enable engineers to select the part for use in equipment. The following explains the test procedure and the relevance to the result.

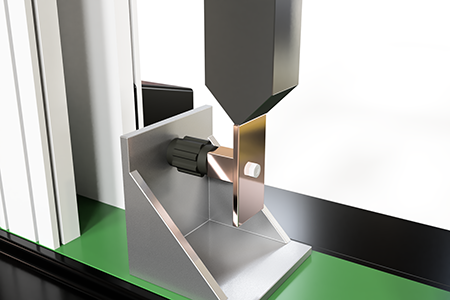

Cantilever Strength

The cantilever strength of an insulator is determined by a cantilever test. The test is intended to evaluate a product’s resistance to a perpendicular force applied to the non fixed end of an insulator, and it is measured in Newtons (N) or Pounds (lb). Depending on the requirements of the individual test specification, the test employs both destructive and non-destructive procedures.

The results provided in our technical tables are the maximum force which Termate recommends the products do not exceed, without elevated risk of permanent damage.

Within some UL Standards, there are specific details of how tests should be performed when assessing their suitability for use in applications such as Panel Boards or Motor Control Centres.

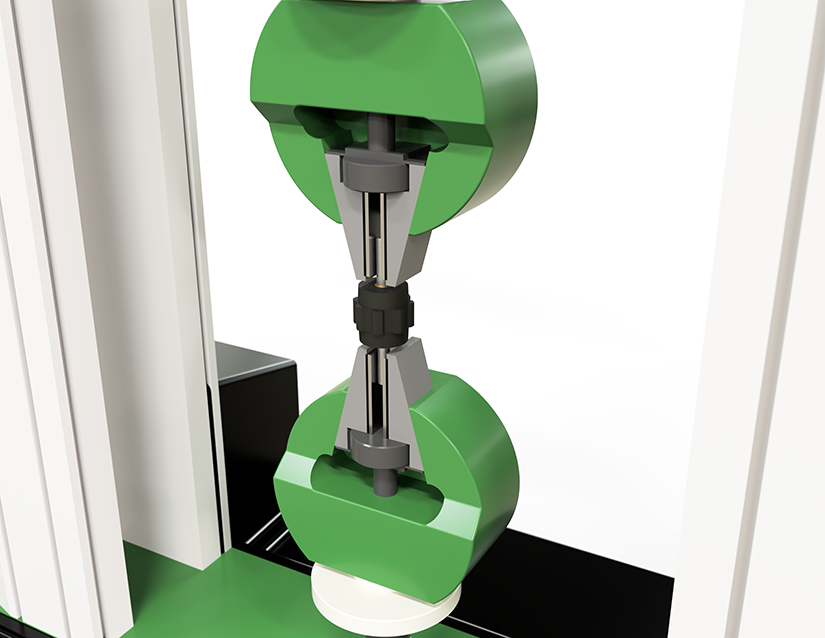

Tensile Strength

The tensile strength of a standoff insulator is also a critical factor in ensuring its reliability under various operating conditions. This property represents the insulator’s ability to withstand longitudinal pulling forces without fracturing. To evaluate tensile strength, a tensile test is conducted, which measures the maximum inline load an insulator can bear before breaking. Results are typically expressed in units of force, such as Newtons (N) or Pounds (lb)

Termate’s technical data provide tensile strength values to guide engineers in selecting appropriate insulators for their applications. It is essential to consider the specific load conditions of the equipment to ensure that the insulator’s tensile strength is adequate to prevent failure.

Torque Strength

Torque strength is another essential parameter for standoff insulators, particularly when they are subjected to rotational forces. This property measures an insulator’s resistance to twisting or turning.

However, the level of force required to damage the insulator body itself, exceeds that of the ability of the material to hold the insert in place. Therefore the data provided in our data, represents the maximum torque to be applied to the bolt or screw being fitted into the insulators insert.

Torque testing involves applying a rotational force to the insert of the insulator until it fails. The results in our technical tables are expressed in Newton-meters (Nm) or Pound-Foot (lb-ft) and represent the maximum recommended tightening torque.

Termate provides torque strength data to assist engineers in selecting insulators capable of withstanding the torsional loads encountered in their equipment. It is crucial to match the insulator’s torque strength to the specific torque requirements of the application to avoid damage or failure.

In addition to these tests being performed by Termate during the initial design, and ongoing development stages of product development. They are also performed on an ongoing basis to ensure that the manufactured products continue to meet the expected performance.

Cantilever tests were also performed independently, by UL, to enable recognised product listing as Panelboard Accessories, Insulator Supports Suitable for use with Annex G of UL891