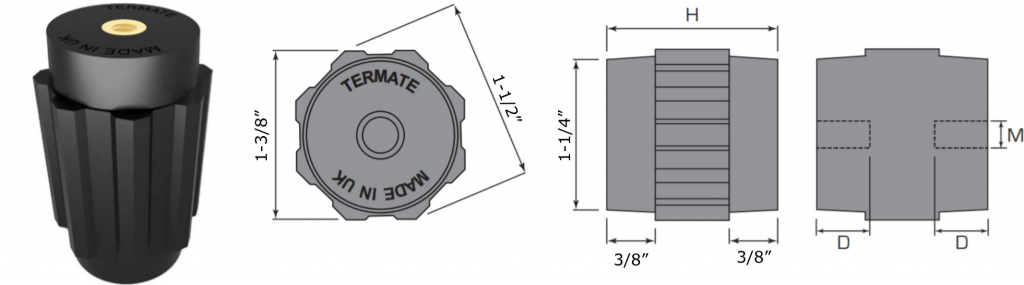

The dimensions and details on this page are specific to the Termate AU4 standoff insulator range.

Technical Data

The below table shows the AU4 range of Termate standoff insulators.

The complete AU4 range is suitable for applications with an AC Equipment Voltage Ue up to 1000 V or DC Equipment Voltage Ue up to 1500 V.

The technical data provided in the table below provides information necessary for product selection and technical assessment in line with IEC and UL product standards.

We hold excellent stock of all of our products and will be happy to provide you a quotation for your requirements, please use our contact us page or email our customer support team.

| Part number | 3D Model | Description | Height [H] † | Thread Size [M]* | Thread Depth [D] | Maximum Tightening Torque (lb·ft) | Tensile Strength** (lb) | Cantilever Strength** (lb) | Box Qty. |

|---|---|---|---|---|---|---|---|---|---|

| AU4-030-014 | AU4-030-014 STEP file | 1.19″ high Standoff Insulator with 1/4UNC thread | 1-3/16″ | ¼″—20 UNC | ⁵⁄₁₆″ | 6 | 2200 | 1200 | 60 |

| AU4-030-516 | AU4-030-516 STEP file | 1.19″ high Standoff Insulator with 5/16UNC thread | 1-3/16″ | ⁵⁄₁₆″—18 UNC | ⅜″ | 17 | 2800 | 1700 | 60 |

| AU4-035-014 | AU4-035-014 STEP file | 1.375″ high Standoff Insulator with 1/4UNC thread | 1-3/8″ | ¼″—20 UNC | ⁵⁄₁₆″ | 6 | 2200 | 1100 | 60 |

| AU4-035-516 | AU4-035-516 STEP file | 1.375″ high Standoff Insulator with 5/16UNC thread | 1-3/8″ | ⁵⁄₁₆″—18 UNC | ⅜″ | 17 | 2900 | 1600 | 60 |

| AU4-035-038 | AU4-035-038 STEP file | 1.375″ high Standoff Insulator with 3/8UNC thread | 1-3/8″ | ⅜″—16 UNC | ⅜″ | 32 | 3400 | 2200 | 60 |

| AU4-040-014 | AU4-040-014 STEP file | 1.56″ high Standoff Insulator with 1/4UNC thread | 1-9/16″ | ¼″—20 UNC | ⁵⁄₁₆″ | 6 | 2200 | 1000 | 50 |

| AU4-040-516 | AU4-040-516 STEP file | 1.56″ high Standoff Insulator with 5/16UNC thread | 1-9/16″ | ⁵⁄₁₆″—18 UNC | ⅜″ | 17 | 2900 | 1500 | 50 |

| AU4-040-038 | AU4-040-038 STEP file | 1.56″ high Standoff Insulator with 3/8UNC thread | 1-9/16″ | ⅜″—16 UNC | ⅜″ | 32 | 3500 | 2100 | 50 |

| AU4-045-014 | AU4-045-014 STEP file | 1.75″ high Standoff Insulator with 1/4UNC thread | 1-3/4″ | ¼″—20 UNC | ⁵⁄₁₆″ | 6 | 2200 | 900 | 50 |

| AU4-045-516 | AU4-045-516 STEP file | 1.75″ high Standoff Insulator with 5/16UNC thread | 1-3/4″ | ⁵⁄₁₆″—18 UNC | ⅜″ | 17 | 3000 | 1400 | 50 |

| AU4-045-038 | AU4-045-038 STEP file | 1.75″ high Standoff Insulator with 3/8UNC thread | 1-3/4″ | ⅜″—16 UNC | ⅝″ | 32 | 3600 | 2000 | 50 |

| AU4-050-014 | AU4-050-014 STEP file | 2″ high Standoff Insulator with 1/4UNC thread | 2″ | ¼″—20 UNC | ⁵⁄₁₆″ | 6 | 2200 | 800 | 25 |

| AU4-050-516 | AU4-050-516 STEP file | 2″ high Standoff Insulator with 5/16UNC thread | 2″ | ⁵⁄₁₆″—18 UNC | ⅜″ | 17 | 3100 | 1300 | 25 |

| AU4-050-038 | AU4-050-038 STEP file | 2″ high Standoff Insulator with 3/8UNC thread | 2″ | ⅜″—16 UNC | ⅝″ | 32 | 3700 | 1900 | 25 |

| AU4-050-012 | AU4-050-012 STEP file | 2″ high Standoff Insulator with 1/2UNC thread | 2″ | ½″—13 UNC | ⅝″ | 56 | 4800 | 2500 | 25 |

| AU4-060-516 | AU4-060-516 STEP file | 2.375″ high Standoff Insulator with 5/16UNC thread | 2-3/8″ | ⁵⁄₁₆″—18 UNC | ⅜″ | 17 | 3200 | 1200 | 25 |

| AU4-060-038 | AU4-060-038 STEP file | 2.375″ high Standoff Insulator with 3/8UNC thread | 2-3/8″ | ⅜″—16 UNC | ⅝″ | 32 | 3800 | 1700 | 25 |

| AU4-060-012 | AU4-060-012 STEP file | 2.375″ high Standoff Insulator with 1/2UNC thread | 2-3/8″ | ½″—13 UNC | ⅝″ | 56 | 4900 | 2100 | 25 |

† Imperial height is approximate, products are manufactured to metric dimensions. (2” = 50mm)

* Fixing details: Hole diameter = Standoff thread size [M]+¹⁄₁₆″

** Tensile and Cantilever Strength figures are based on tests carried out at normal room temperature, nominal 73.4 °F

The following tables shows the Recognition, Properties and Characteristics of the AU4 range of Termate standoff insulators.

| Recognition | Reference / Link | Preferred name |

|---|---|---|

| UL Recognised Component | File Number: E505645 | |

| EClass 8.0 | 27-08-10-08 | Insulator, plastic |

| EClass 14.0 | 27-08-10-03 | Bus bar holder (insulator, post insulator) |

| Properties | Value / Measure / Unit |

|---|---|

| Insulator Material | Glass Reinforced Polyamide 6.6 (PA66) |

| Insert Material | Brass |

| Operating Range in Fahrenheit | This material operates in a wide temperature range: −40 °F to +266 °F |

| Operating Range in Celsius | This material operates in a wide temperature range: −40 °C to +130 °C |

| Flammability | UL 94 V-0 |

| Oxygen Index | 32% |

| Glow Wire | 960 °C |

| Characteristics | Value |

|---|---|

| Maximum Alternating Current Equipment Voltage, Ue | 1000 V |

| Maximum Direct Current Equipment Voltage, Ue | 1500 V |

| Impulse Voltage, Uimp | 12 kV |

The following table provides additional UL Yellow Card information, for the material used in AU4 standoff insulator range, required for assessing the suitability for incorporation into electrical equipment built to North American standards or for use when evaluating unlisted equipment for compliance with North American recognised standards, using methods such as NFPA 791.

| Properties | Value | Test Method |

|---|---|---|

| Hot-wire Ignition (HWI) | PLC 0 | UL 746A |

| High Amp Arc Ignition (HAI) | PLC 1 | UL 746A |

| Comparative Tracking Index (CTI) | PLC 0 | UL 746A |

| UV Exposure & Water Immersion | f1 | UL 746C |

Standoff Insulators:

Manufacture:

Termate’s AU4 standoff insulator range provides excellent electrical insulation and mechanical strength for a variety of applications. Standoff insulators can also be referred to as post insulators, egg insulators, bobbin insulators, or busbar isolators.

This standoff insulator range is available in heights from 1³⁄₁₆ inch to 2⅜ inch and insert sizes of ¼″-20 to ½″—13 UNC. Technical data is found on the table above which displays heights, thread size and depth, maximum tightening torques, tensile and cantilever strengths, and box quantities available.

Please note that while we have referenced imperial (inch) dimensions, the height and width of the range is identical to the metric sizes. The .STEP files attached are the correct dimensions.

- Made from UL 94 V-0 rated, self-extinguishing material

- Halogen Free

- Operating temperature range of −40 °F to +266 °F

- Insulation voltage of up to 1000 V AC, 1500 V DC

- Equipment voltage of up to 1000 V AC, 1500 V DC

- UL Recognised Component; file number E505645

Our standoff insulators are made from a halogen-free glass-reinforced material, which was specifically chosen for its mechanical and electrical insulation properties.

Brass inserts are used due to this alloy’s resistance to corrosion. The injection moulding process, combined with our excellent quality control and inspection procedures, results in a consistent product across every production run.

Testing:

Termate carries out rigorous and appropriate testing on all our products. The AU4 range of standoff insulators successfully passed extensive testing to ensure their electrical and mechanical capabilities.

Termate has obtained UL Component Recognition for our insulators. Where applicable, they comply with both UL891 Annex G and UL508A Annex D for brace and support requirements for panelboard and switchboard accessories.

AU4 standoff insulators meet the requirements for UL 94 V-0. UL 94 being a standard for the safety of flammability of plastic materials for parts in devices and appliances released by the Underwriters Laboratories.

Our Standoff insulator range is a UL Recognised Component and are listed under the product category “Panelboard and Switchboard Accessories – Component”, more information can be found at UL Product IQ.

- Energy Storage Systems and Equipment (UL9540)

- Electrical Panelboards (UL67)

- Industrial Control Panels (UL508A)

- Switchboards (UL891)

- Metal-Enclosed Low-Voltage Power Circuit Breaker Switchgear (UL 1558)

- Inverters, Converters, Controllers and Interconnection System Equipment for Use With Distributed Energy Resources (UL1741)

Termate is committed to the highest standard of customer focus and we have made every effort to maintain the accuracy and completeness of the information provided in this data. Where improvements to our products affect their installation and usage we endeavour to contact any customers who may be affected.

Warranty as stated in our Terms and Conditions of Trading is void if any modification is made to the warranted product.