Pillar Insulators

Our pillar insulator range is designed to provide exceptional electrical insulation and mechanical support in a wide range of applications, including Railway Application’s where EN 45545-2 applies.

Should you require a larger insulator please review our AM1 Insulator Range

or for Railway Application’s review our RAM1 Insulator Range

Made from specialised polyamide, selected to meet railway application requirements, our pillar insulators offers high mechanical and insulating capabilities.

- Halogen and phosphorus free

- EN 45545-2:2020 – EL10 (R26)

Technical Data

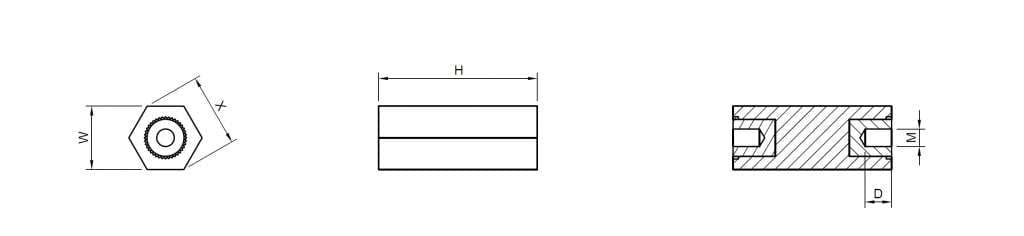

Female/Female Pillar Insulators

| Part Number | 3D Model | Height [H] (mm) | Width AF [W] (mm) | Width AC [X] (mm) | Thread Size* [M] | Thread Depth [D] (mm) | Maximum Tightening Torque (N·m) | Box Qty. |

|---|---|---|---|---|---|---|---|---|

| 3M420F | 3M420F STEP file | 20 | 12 | 14 | M4 | 5 | 2 | 200 |

| 3M520F | 3M520F STEP file | 20 | 12 | 14 | M5 | 5 | 4 | 200 |

| 3M425F | 3M425F STEP file | 25 | 12 | 14 | M4 | 5 | 2 | 200 |

| 3M525F | 3M525F STEP file | 25 | 12 | 14 | M5 | 5 | 4 | 200 |

| 3M430F | 3M430F STEP file | 30 | 12 | 14 | M4 | 5 | 2 | 200 |

| 3M530F | 3M530F STEP file | 30 | 12 | 14 | M5 | 5 | 4 | 200 |

| 3M540F | 3M540F STEP file | 40 | 12 | 14 | M5 | 5 | 4 | 100 |

| 3M550F | 3M550F STEP file | 50 | 12 | 14 | M5 | 5 | 4 | 100 |

| 3M560F | 3M560F STEP file | 60 | 12 | 14 | M5 | 5 | 4 | 100 |

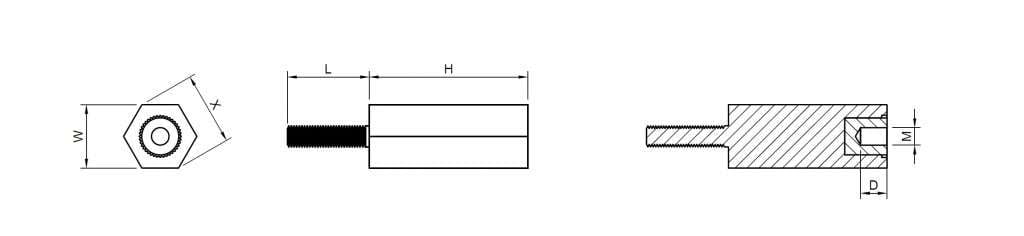

Male/Female Pillar Insulators

| Part Number | 3D Model | Height [H] (mm) | Width AF [W] (mm) | Width AC [X] (mm) | Thread Size* [M] | Thread Depth [D] (mm) | Length [L] (mm) | Maximum Tightening Torque (N·m) | Box Qty. |

|---|---|---|---|---|---|---|---|---|---|

| 3M415H | 3M415H STEP file | 15 | 12 | 14 | M4 | 5 | 16 | 2 | 200 |

| 3M515H | 3M515H STEP file | 15 | 12 | 14 | M5 | 5 | 14 | 4 | 200 |

| 3M420H | 3M420H STEP file | 20 | 12 | 14 | M4 | 5 | 16 | 2 | 200 |

| 3M520H | 3M520H STEP file | 20 | 12 | 14 | M5 | 5 | 14 | 4 | 200 |

| 3M525H | 3M525H STEP file | 25 | 12 | 14 | M5 | 5 | 14 | 4 | 200 |

| 3M430H | 3M430H STEP file | 30 | 12 | 14 | M4 | 5 | 16 | 2 | 200 |

| 3M530H | 3M530H STEP file | 30 | 12 | 14 | M5 | 5 | 14 | 4 | 200 |

| 3M540H | 3M540H STEP file | 40 | 12 | 14 | M5 | 5 | 14 | 4 | 100 |

| 3M550H | 3M550H STEP file | 50 | 12 | 14 | M5 | 5 | 14 | 4 | 100 |

| 3M560H | 3M560H STEP file | 60 | 12 | 14 | M5 | 5 | 14 | 4 | 100 |

Male/Male Pillar Insulators

| Part Number | 3D Model | Height [H] (mm) | Width AF [W] (mm) | Width AC [X] (mm) | Thread Size* [M] | Length [L] (mm) | Maximum Tightening Torque (N·m) | Box Qty. |

|---|---|---|---|---|---|---|---|---|

| 3M415M | 3M415M STEP file | 15 | 12 | 14 | M4 | 16 | 2 | 200 |

| 3M515M | 3M515M STEP file | 15 | 12 | 14 | M5 | 14 | 4 | 200 |

| 3M420M | 3M420M STEP file | 20 | 12 | 14 | M4 | 16 | 2 | 200 |

| 3M520M | 3M520M STEP file | 20 | 12 | 14 | M5 | 14 | 4 | 200 |

| 3M525M | 3M525M STEP file | 25 | 12 | 14 | M5 | 14 | 4 | 200 |

| 3M430M | 3M430M STEP file | 30 | 12 | 14 | M4 | 16 | 2 | 200 |

| 3M530M | 3M530M STEP file | 30 | 12 | 14 | M5 | 14 | 4 | 200 |

| 3M540M | 3M540M STEP file | 40 | 12 | 14 | M5 | 14 | 4 | 100 |

* Fixing details: Hole diameter = Standoff thread size [M]+1 mm. e.g. M6 Thread = 7 mm hole diameter.

Our Insulators have ISO M inserts with coarse threaded inserts in accordance with BS 3643-2 – Table 1 and ISO 262

Properties

Material

Zero halogen and phosphorus free polyamide 6 (PA6) with low smoke emissions and flame retardant

Female Insert Material

Brass

Male Insert Material

Mild Steel, Zinc Plated & Passivated

Operating Temperature

Flammability

V-0, to IEC 60695-11-10

Product Number to EN 45545-2:2020

EL10

Oxygen Index

32%

Glow Wire

Characteristics

Manufacture:

Our Pillar Insulators are made from halogen and phosphorus free Polyamide 6 (PA6) with low smoke emissions and flame retardant. This material has been independently tested and complies with R26 requirements of EN 45545-2:2020.

TESTING:

As with all Termate products, our Pillar Insulators have been subjected to expert testing in order to ensure suitability for their intended application. Each range is fully compliant with the applicable clauses within the international standard for low-voltage switchgear and controlgear assemblies, IEC 61439.

We can review compliance with other standards upon request. In addition, the material for this range has been historically tested for reaction to fire, opacity of smoke and toxicity of gases emitted to the withdrawn French National Standard NF F16 101/102 with a result of I3/F2 .

Our testing procedure is designed to give you the confidence that, when correctly installed in your own assembly, our products will meet the specified ratings.

Application:

Our Pillar Insulators are designed to provide insulated support in assemblies that include live conductors, maintaining the distance between two surfaces to ensure they do not touch.

Additionally, our Pillars are optimised to meet specific demands on flammability and release of particulates during a fire. They are suitable for use in;

- electronics and motors,

- underground rail rolling stock,

- tunnels,

- marine,

- mining and oil and gas applications

It is essential that you ensure our range is fully compliant with your specific requirements prior to use; our highly experienced team are available to provide more technical details and advise on product use.

Related Products