At Termate we help customers to understand what is important for electrical insulation components, this time looking at what a busbar support is. If you have any topics you’d like us to consider for future articles, please contact our customer support team.

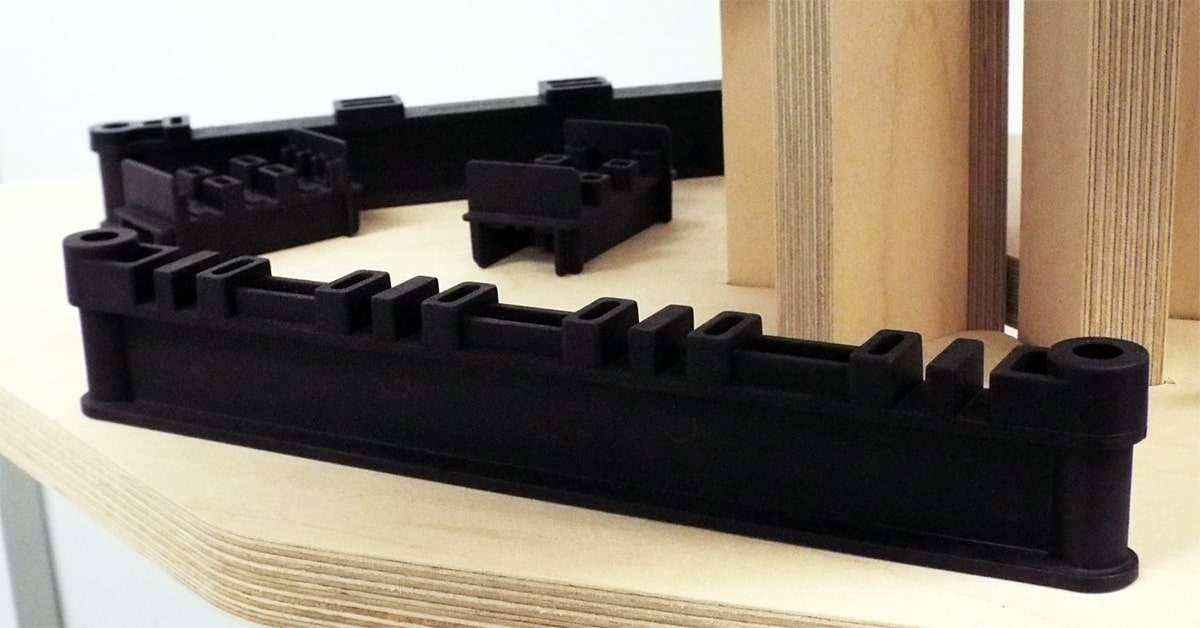

Busbar supports, also known as busbar clamps or busbar braces, are electrically insulating supports designed to hold live electrical conductors known as busbars.

Busbars are used in a wide range of electrical applications, including high-voltage, medium-voltage, and low-voltage switchgear and controlgear assemblies. These insulating supports secure copper or aluminium busbars within an enclosure and hold them safely during critical moments, such as short circuits.

Low voltage busbar supports can be made of a number of materials, including polyamide 6.6, dough-moulded compound, GP03, and other polymers.

Manufacturers must use materials with high electrical resistance since electrical resistance is a crucial feature of busbar supports. They can be manufactured to hold busbars in different arrangements.

Variations may include the number of phases (such as L1, L2, and L3 in a 3-phase system), poles, and bars per pole. For example, our MX supports are used to build a three- or four-pole busbar system.

- The material it is made from.

- The operating/conductor temperature it can continuously withstand.

- Flammability rating of the material (i.e., UL 94 V-0).

- Glow wire test temperature of the material.

- Equipment voltage (Ue).

- Insulation voltage (Ui).

- Impulse voltage (Uimp).

- Short-Circuit Withstand Capacity rating (Icw)

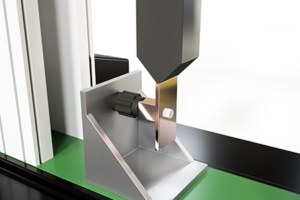

Busbar supports have no product standard of their own, but they should be manufactured and tested to meet the ratings associated with their intended application. This can be done by meeting the requirements of certain clauses within the application’s product standard, such as BS EN IEC 61439 for low voltage switchgear and controlgear assemblies.

To understand the capability of an insulating support, manufacturers can send samples to third-party laboratories, or they can test in-house if they have suitable equipment. A safety margin is typically included in published data to account for minor material and manufacturing tolerances. Based on this, we can provide customers with a declaration of rating.