At Termate we help customers to understand what is important for electrical insulation components, this time looking at cantilever strength. If you have any topics you’d like us to consider for future articles, please contact our customer support team.

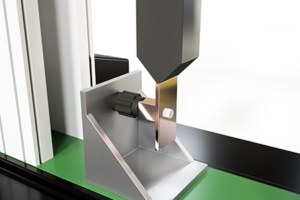

The cantilever strength of an insulator is determined by a cantilever test. The test is intended to evaluate a product’s resistance to a perpendicular force, and it is measured in newtons. Depending on the requirements of the individual test specification, the test employs both destructive and non-destructive procedures.

However, in non-destructive procedures, a specified cantilever load can be used to best represent the ultimate cantilever strength of a standoff insulator when under cantilever forces. Specified cantilever loads are influenced by historical tests where the insulator has failed. The specified cantilever load is either equal to or less than the cantilever breaking load. If you’re seeking to buy an insulator, the specified cantilever load is the value that a manufacturer could choose to best represent the ultimate cantilever strength rating of a standoff insulator.

Other cantilever measurements are also useful in understanding how a standoff insulator may perform in an assembly, such as the maximum design/reference load. This rating determines how much weight can be applied to the insulator every day without damaging the insulator’s service life.

When a short-circuit occurs in a busbar system, the insulator will be put under extreme forces, one of which is a strong perpendicular force. The standoff insulator must withstand these forces and hold the busbar safely. This is only one of many examples of why insulators would need both good electrical insulation and mechanical support properties.

Temperature, for example, can influence the testing outcome of an insulator. Manufacturers can state at what environmental temperature the standoff insulator was tested at. For example, the standoff insulators we manufacture are tested at a normal room temperature (nominal 23 °C).

Cantilever testing should be important for any standoff insulator. They should meet the appropriate clauses of national or international standards relevant to their application, such as for low-voltage switchgear and controlgear assemblies, BS EN IEC 61439.

Learn more and find detailed technical data on our standoff insulators.