Termate are proud to report that the new centralised moulding facility has been commissioned and is fully operational.

When we purchased two additional injection presses in January 2022 for delivery in May 2022, we knew that we didn’t have the space in our existing mould shop. We instigated a program of work including extensive civil, mechanical and electrical works to modify and modernise various aspects of our factory.

Following the successful completion of phase 1 of the project, our 2 new additions were operational, and inline with our plan, we have now moved our existing machines to join them.

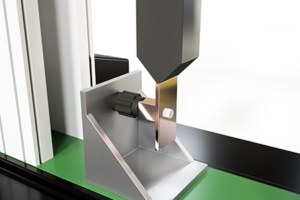

Further technological advancements are coming with the introduction of automation.

Our focus now turns to further expansion programs, with our logistics department and compression moulding facility being priorities.

We have made large investments in elevated product stocks as well as additional tooling to keep ahead of high customer demands.

Our stock levels of popular products such as Standoff Insulators now enable a rapid response.