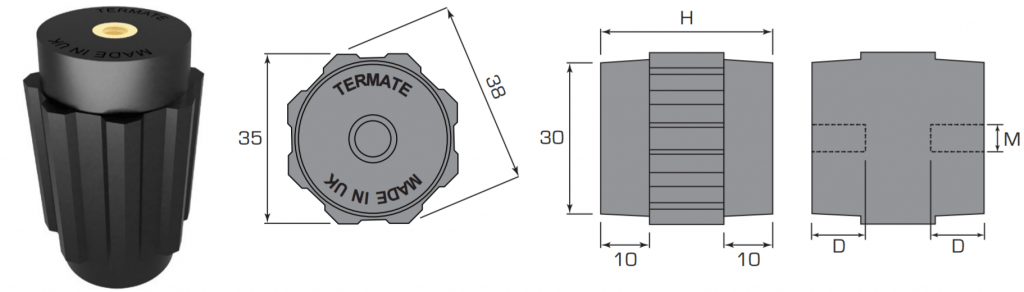

The dimensions and details on this page are specific to the Termate AM4 standoff insulator range.

Technical Data for AM4 standoff insulators

The below table shows the AM4 range of Termate standoff insulators.

The complete AM4 range is suitable for applications with an AC Equipment Voltage Ue up to 1000 V or DC Equipment Voltage Ue up to 1500 V.

The technical data provided in the table below provides information necessary for product selection and technical assessment in line with IEC and UL product standards.

We hold excellent stock of all of our products and will be happy to provide you a quotation for your requirements, please use our contact us page or email our customer support team.

| Part number | 3D Model | Description | Height [H] (mm) | Thread Size* [M] | Thread Depth [D] (mm) | Maximum Tightening Torque (N·m) | Tensile Strength** (N) | Cantilever Strength** (N) | Box Qty. |

|---|---|---|---|---|---|---|---|---|---|

| AM4-030-06 | AM4-030-06 STEP file | 30mm high standoff insulator with M6 thread | 30 | M6 | 7 | 11 | 12300 | 6400 | 60 |

| AM4-030-08 | AM4-030-08 STEP file | 30mm high standoff insulator with M8 thread | 30 | M8 | 9 | 28 | 15500 | 9300 | 60 |

| AM4-035-06 | AM4-035-06 STEP file | 35mm high standoff insulator with M6 thread | 35 | M6 | 7 | 11 | 12300 | 6000 | 60 |

| AM4-035-08 | AM4-035-08 STEP file | 35mm high standoff insulator with M8 thread | 35 | M8 | 9 | 28 | 15900 | 8800 | 60 |

| AM4-035-10 | AM4-035-10 STEP file | 35mm high standoff insulator with M10 thread | 35 | M10 | 10 | 55 | 19000 | 12400 | 60 |

| AM4-040-06 | AM4-040-06 STEP file | 40mm high standoff insulator with M6 thread | 40 | M6 | 7 | 11 | 12200 | 5500 | 50 |

| AM4-040-08 | AM4-040-08 STEP file | 40mm high standoff insulator with M8 thread | 40 | M8 | 11 | 28 | 16300 | 8400 | 50 |

| AM4-040-10 | AM4-040-10 STEP file | 40mm high standoff insulator with M10 thread | 40 | M10 | 10 | 55 | 19500 | 11800 | 50 |

| AM4-045-06 | AM4-045-06 STEP file | 45mm high standoff insulator with M6 thread | 45 | M6 | 7 | 11 | 12200 | 5000 | 50 |

| AM4-045-08 | AM4-045-08 STEP file | 45mm high standoff insulator with M8 thread | 45 | M8 | 11 | 28 | 16700 | 7900 | 50 |

| AM4-045-10 | AM4-045-10 STEP file | 45mm high standoff insulator with M10 thread | 45 | M10 | 16 | 55 | 20000 | 11200 | 50 |

| AM4-050-06 | AM4-050-06 STEP file | 50mm high standoff insulator with M6 thread | 50 | M6 | 7 | 11 | 12200 | 4600 | 25 |

| AM4-050-08 | AM4-050-08 STEP file | 50mm high standoff insulator with M8 thread | 50 | M8 | 11 | 28 | 17100 | 7400 | 25 |

| AM4-050-10 | AM4-050-10 STEP file | 50mm high standoff insulator with M10 thread | 50 | M10 | 16 | 55 | 20500 | 10600 | 25 |

| AM4-050-12 | AM4-050-12 STEP file | 50mm high standoff insulator with M12 thread | 50 | M12 | 16 | 95 | 26600 | 14000 | 25 |

| AM4-060-08 | AM4-060-08 STEP file | 60mm high standoff insulator with M8 thread | 60 | M8 | 11 | 28 | 17900 | 6500 | 25 |

| AM4-060-10 | AM4-060-10 STEP file | 60mm high standoff insulator with M10 thread | 60 | M10 | 16 | 55 | 21400 | 9500 | 25 |

| AM4-060-12 | AM4-060-12 STEP file | 60mm high standoff insulator with M12 thread | 60 | M12 | 16 | 95 | 27100 | 11400 | 25 |

* Fixing details: Hole diameter = Standoff thread size [M]+1 mm. e.g. M6 Thread = 7 mm hole diameter

** Tensile and Cantilever Strength figures are based on tests carried out at normal room temperature, nominal 23 °C

Our Insulators have ISO M inserts with coarse threaded inserts in accordance with BS 3643-2 – Table 1 and ISO 262

Our metric insulators can be converted into Male/Male or Female/Male versions by fitting studs from our Grub Screw Pack.

The following tables shows the Recognition, Properties and Characteristics of the AM4 range of Termate standoff insulators.

| Recognition | Reference / Link | Preferred name |

|---|---|---|

| UL Recognised Component | File Number: E505645 | |

| EClass 8.0 | 27-08-10-08 | Insulator, plastic |

| EClass 14.0 | 27-08-10-03 | Bus bar holder (insulator, post insulator) |

| Properties | Value / Measure / Unit |

|---|---|

| Insulator Material | Glass Reinforced Polyamide 6.6 (PA66) |

| Insert Material | Brass |

| Operating Range in Celsius | This material operates in a wide temperature range: −40 °C to +130 °C |

| Operating Range in Fahrenheit | This material operates in a wide temperature range: −40 °F to +266 °F |

| Flammability | UL 94 V-0 |

| Oxygen Index | 32% |

| Glow Wire | 960 °C |

| Characteristics | Value |

|---|---|

| Maximum Alternating Current Equipment Voltage, Ue | 1000 V |

| Maximum Direct Current Equipment Voltage, Ue | 1500 V |

| Impulse Voltage, Uimp | 12 kV |

The following table provides additional UL Yellow Card information, for the material used in AM4 standoff insulator range, required for assessing the suitability for incorporation into electrical equipment built to North American standards or for use when evaluating unlisted equipment for compliance with North American recognised standards, using methods such as NFPA 791.

| Properties | Value | Test Method |

|---|---|---|

| Hot-wire Ignition (HWI) | PLC 0 | UL 746A |

| High Amp Arc Ignition (HAI) | PLC 1 | UL 746A |

| Comparative Tracking Index (CTI) | PLC 0 | UL 746A |

| UV Exposure & Water Immersion | f1 | UL 746C |

Standoff Insulators:

Suitable for a variety of assemblies, the AM4 standoff insulator range supplies excellent mechanical strength and electrical insulation.

Post insulators, egg insulators, bobbin insulators, and busbar isolators are all terms used to describe standoff insulators.

Our AM4 insulating standoffs come in different heights from 30 mm to 60 mm, as well as insert sizes of M6 to M12. Heights, thread depths and sizes, maximum tightening torques, cantilever and tensile strengths, and box quantities are all listed in the table above.

The AM4 insulators have the following properties:

- Halogen Free

- Equipment voltage of up to 1000 V AC, 1500 V DC

- Insulation voltage of up to 1000 V AC, 1500 V DC

- Operating temperature ranging from −40 °C to +130 °C

- UL Recognised Component; file number E505645

- Made from UL 94 V-0 rated, self-extinguishing material

Manufacture:

Termate AM4 standoff insulators are manufactured from halogen free glass-reinforced polyamide 6.6 material and contain precision threaded brass alloy inserts for greater corrosion resistance.

The injection moulding process we use to manufacture our electrical insulating parts improves overall product quality and design accuracy.

Testing:

Product testing is critical for any component that will be used in an electrical or mechanical system.

Professional, thorough, and independent testing has been performed on the AM4 standoff insulator range to assure efficacy when installed correctly in their intended assembly.

Our Standoff insulator range is a UL Recognised Component, more information can be found at UL Product IQ.

One of the most widely used tests for determining the ability of plastic parts to self-extinguish after the heat source has been removed is UL 94. All Termate standoffs meet V-0 requirements for the UL 94 test standard.

Our standoff insulators have undergone comprehensive testing, including cantilever, torque, and tensile tests, to give you peace of mind that they will fulfil specified ratings when fitted appropriately.

Application:

These standoff insulators are designed to hold live busbars and other active conductors as an insulating support, safely and securely, by keeping a gap between two surfaces and is appropriate for assemblies up to 1000 V AC & 1500 V DC.

The electrical insulation and mechanical strength of the support are critical in these types of systems.

A list of some of the most common applications for our insulators include:

- Battery Energy Storage Systems

- Electrical panel boards

- Control panels

- Switchboards

- EV power trains

- Power factor correction

- Distribution boards

- Generators

- Switchgear

- Controlgear

- Drives, inverters and converters.

Power distribution, rail (rolling stock & trackside), renewable energy, UPS (temporary and emergency power), and data centre power distribution are all examples of sectors where these electrical installations and assemblies are used.

For over 60 years, Termate has designed and manufactured electrical insulating parts and components at our UK-based site. Every insulating plastic product we make is of the highest quality so that we can provide electrical insulating solutions that are safe and suitable for purpose. By becoming a part of our portfolio of trusted customers, we can provide time-effective results for your projects.

Termate is committed to the highest standard of customer focus and we have made every effort to maintain the accuracy and completeness of the information provided in this data. Where improvements to our products affect their installation and usage we endeavour to contact any customers who may be affected.

Warranty as stated in our Terms and Conditions of Trading is void if any modification is made to the warranted product.