Low Smoke Standoff Insulators

The Low Smoke range of Standoff Insulators is designed to provide exceptional electrical insulation and mechanical support in applications where low smoke emissions and high fire retardancy are required.

Made from specialised glass-reinforced polyester DMC, selected to meet NF F16- 101/102 requirements, our range offers high mechanical and insulating capabilities while simultaneously ensuring burning and smoke toxicity standards are met.

The Termate range of low-smoke insulating standoffs include a comprehensive variety of styles, heights and insert sizes.

Please note: due to the specialist nature of the material, these parts are made to order.

This product range has reached end of life. They have been discontinued. Please visit here for our replacement range.

Technical Data

| Part number | Height [H] (mm) | Width AF [W] (mm) | Width AC [X] (mm) | Thread Size [M]* | Thread Depth [D] (mm) |

|---|---|---|---|---|---|

| LSH625 | 25 | 25 | 29 | M6 | 7 |

| LSH835 | 35 | 25 | 29 | M8 | 10 |

| LSH840 | 40 | 25 | 29 | M8 | 10 |

| LSH845 | 45 | 25 | 29 | M8 | 10 |

| LSH850 | 50 | 25 | 29 | M8 | 10 |

| LSH860 | 60 | 25 | 29 | M8 | 10 |

| LSH835H28 | 35 | 25 | 29 | M8 | 10 |

| LSH840H28 | 40 | 25 | 29 | M8 | 10 |

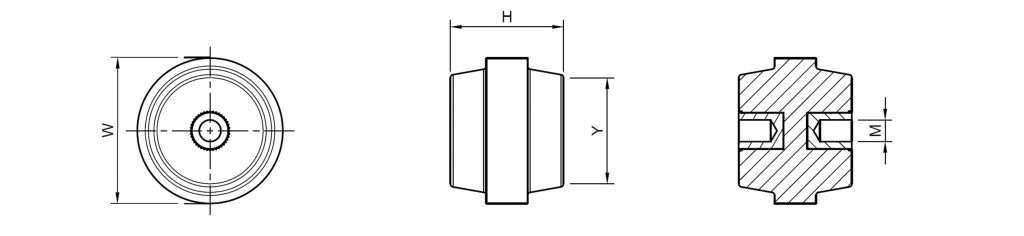

| Part number | Height [H] (mm) | Width [W] (mm) | Thread Size [M]* | Thread Depth [D] (mm) |

|---|---|---|---|---|

| L3635 | 35 | 46 | M6 | 10 |

| L3835 | 35 | 46 | M8 | 10 |

| L31035 | 35 | 46 | M10 | 10 |

| LSO1045 | 45 | 46 | M10 | 10 |

| LSO850 | 50 | 46 | M8 | 10 |

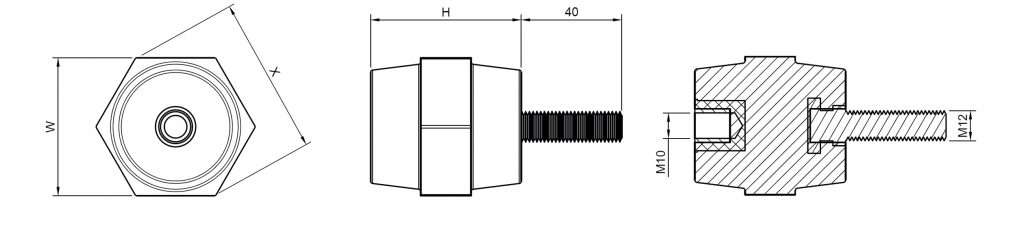

| Part number | Height [H] (mm) | Width AF [W] (mm) | Width AC [X] (mm) | Thread Size [M]* | Thread Depth [D] (mm) |

|---|---|---|---|---|---|

| L3850 | 51 | 51 | 55 | M8 | 10 |

| L31050 | 51 | 51 | 55 | M10 | 16 |

| L31250 | 51 | 51 | 55 | M12 | 16 |

| Part number | Height [H] (mm) | Width AF [W] (mm) | Width AC [X] (mm) | Thread Size [M]* | Thread Depth [D] (mm) |

|---|---|---|---|---|---|

| L3860 | 60 | 55 | 64 | M8 | 10 |

| L31060 | 60 | 55 | 64 | M10 | 16 |

| L31260 | 60 | 55 | 64 | M12 | 16 |

| L31660 | 60 | 55 | 64 | M16 | 22 |

| L3870 | 70 | 55 | 64 | M8 | 10 |

| L31070 | 70 | 55 | 64 | M10 | 16 |

| L31270 | 70 | 55 | 64 | M12 | 16 |

| L31060M12 | 60 | 55 | 64 | M10/12 | 16 |

* Fixing details: Hole diameter = Standoff thread size [M]+1 mm. e.g. M6 Thread = 7 mm hole diameter.

Other sizes of Low Smoke Standoff Insulators may be available. Please contact our team for more information.

Properties

Material

Female Insert Material

Brass

Male Insert Material

Mild Steel, Zinc Plated & Passivated

Operating Temperature

Flammability

V0, to IEC 60695-11-10

NF F Classification

16-101/102, I0, F0

Oxygen Index

70%

Glow Wire

Characteristics

Application:

Our Low Smoke Standoff Insulators are designed to provide insulated support in assemblies that have to meet specific demands on flammability and release of particulates during a fire.

They are suitable for use in underground rail rolling stock, tunnels, marine, mining and oil and gas applications.

It is essential that you ensure our range is fully compliant with your specific requirements prior to use; our highly experienced team are available to provide more technical details and advise on product use.

Manufacture:

Our insulators are made from specialised DMC (dough moulded compound) with additives for high fire retardancy and low particulate emissions.

This material has been independently tested and complies with the NF F16 101/102 requirements as stated.

Testing:

As with all Termate products, our Low Smoke Standoff Insulators have been subjected to expert testing in order to ensure suitability for their intended application.

We can review compliance with other standards upon request. In addition, the material for this range has been subjected to specific testing for reaction to fire, opacity of smoke and toxicity of gases emitted.

Our testing procedure is designed to give you the confidence that, when correctly installed in your own assembly, our products will meet the specified ratings.

Termate have been expertly manufacturing specialised insulation products in the heart of the UK for more than 60 years. We are dedicated to applying our engineering expertise in order to design and manufacture top-of-the-range components, so you can be assured that our products will be high quality.

Our in-house product development team constantly seeks to improve existing products and develop new, innovative parts for our customers.

Termate is committed to the highest standard of customer focus and we have made every effort to maintain the accuracy and completeness of the information provided in this data. Where improvements to our products affect their installation and usage we endeavour to contact any customers who may be affected.

Warranty as stated in our Terms and Conditions of Trading is void if any modification is made to the warranted product.

Related Products